三种半定量职业健康风险评估方法在汽车整车制造业中的应用

YE Wei-ping, ZHANG Cheng, LIANG Jiao-jun, MAO Geshi, CHEN Zhen-long. Application of three semi-quantitative occupational health risk assessment methods in automobile manufacturing enterprises[J]. Journal of Environmental and Occupational Medicine, 2020, 37(2): 150-156. DOI: 10.13213/j.cnki.jeom.2020.19596

Citation: YE Wei-ping, ZHANG Cheng, LIANG Jiao-jun, MAO Geshi, CHEN Zhen-long. Application of three semi-quantitative occupational health risk assessment methods in automobile manufacturing enterprises[J]. Journal of Environmental and Occupational Medicine, 2020, 37(2): 150-156. DOI: 10.13213/j.cnki.jeom.2020.19596

三种半定量职业健康风险评估方法在汽车整车制造业中的应用

武汉市职业病防治院职业卫生科, 湖北 武汉 430015

基金项目: 国家职业卫生标准体系建设项目(131031109000160010)

详细信息

作者简介:叶伟平(1984-), 男, 硕士, 主管医师; E-mail:13377881745@163.com

通讯作者:陈振龙, E-mail:77785338@qq.com

组稿专家 张美辨(浙江省疾病预防控制中心职业健康与辐射防护所),E-mail:mbzhang@cdc.zj.cn

利益冲突 无申报

中图分类号: R13

计量 文章访问数: 03119 HTML全文浏览量: 0 PDF下载量: 0610 出版历程 收稿日期: 2019-08-29 录用日期: 2019-12-29 网络出版日期: 2022-11-20 刊出日期: 2020-02-24Application of three semi-quantitative occupational health risk assessment methods in automobile manufacturing enterprises

Occupational Health Department, Wuhan Prevention and Treatment Center for Occupational Diseases, Wuhan, Hubei 430015, China

Funds: This study was funded

More Information

Corresponding author:CHEN Zhen-long, E-mail: 77785338@qq.com

摘要

摘要:

背景

汽车整车制造企业在生产过程中存在粉尘、化学毒物等职业病危害因素,会对作业人员的健康产生不良影响。

目的

应用GBZ/T 298-2017《工作场所化学有害因素职业健康风险评估技术导则》中的三种半定量风险评估方法对汽车制造企业进行职业健康风险评估,探索其适用条件。

方法

采用判断抽样方法,从湖北省武汉市6家整车制造企业中选取4家,对接触职业病危害因素的主要岗位进行职业健康风险评估,并对三种方法的评估结果进行比较和验证。

结果

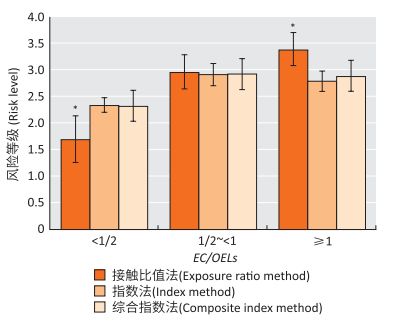

4家汽车整车制造企业的主要职业病危害因素为电焊烟尘、砂轮磨尘、锰及其无机化合物、二氧化氮、甲苯、二甲苯、丁酮、乙酸丁酯、丁醇、异丙醇。接触比值法评估结果显示,C、D企业熔化极惰性气体保护(melt inert-gas,MIG)焊岗位为高风险岗位。指数法评估结果显示,各企业的点焊、打磨岗位和A、C、D企业的MIG焊岗位为中等风险岗位。综合指数法评估结果与指数法相同。当接触浓度(exposure concentration,EC) < 1/2职业接触限值(occupational exposure levels,OELs)时,接触比值法的风险指数(risk,R)(1.694±0.433)低于指数法(2.344±0.317)和综合指数法(2.327±0.317)(P < 0.001);当1/2 OELs ≤ EC <OELs时,接触比值法的R(2.966±0.138)与指数法(2.916±0.206)和综合指数法(2.924±0.195)之间的差异无统计学意义(P>0.05);当EC ≥ OELs时,接触比值法的R(3.398±0.289)高于指数法(2.802±0.283)和综合指数法(2.887±0.279)(P < 0.001)。接触比值法与指数法的评估结果一致性差(加权Kappa=0.118,P < 0.001),与综合指数法的评估结果一致性差(加权Kappa=0.136,P < 0.001),指数法与综合指数法的评估结果一致性极好(加权Kappa=0.977,P < 0.001)。EC超过OELs的岗位,三种评估结果为中等风险以上,与OELs的判定结果相符。手工喷漆岗位在三种评估方法中被评估为可忽略风险岗位和低风险岗位,与职业健康监护结果不一致。

结论

三种半定量方法均能识别重点岗位,但是对于手工喷漆岗位的风险评估结果偏保守。三种半定量风险评估结果与EC有关,可根据职业病危害因素的EC,选择合适的评估方法。

Abstract:

Background

Occupational hazards such as dust and toxic chemicals in the production process of automobile manufacturers will adversely affect the health of workers.

Objective

This study applies three semi-quantitative risk assessment methods in GBZ/T 298-2017 Guidelines for occupational health risk assessment of chemicals in the workplace to assess the occupational health risk in automobile manufacturing enterprises and explores their applicability.

Methods

Judgment sampling method was used to select four out of six automobile manufacturing enterprises in Wuhan City, Hubei Province to conduct occupational health risk assessment for the main positions exposed to occupational hazards, and the results of three occupational health risk assessment methods were compared and verified.

Results

The major occupational hazards of the four automobile manufacturers were welding fume, grinding wheel dust, manganese and its inorganic compounds, nitrogen dioxide, toluene, xylene, methyl ethyl ketone, butyl acetate, butanol, and isopropyl alcohol. The results of exposure ratio method showed that the melt inert-gas (MIG) welding positions of companies C and D were high-risk positions. The results of index method showed that the spot welding and polishing positions of the four companies and the MIG welding positions of companies A, C, and D were medium-risk positions. The results of composite index method were the same as the index method. When exposure concentration (EC) was less than 1/2 of the relevant national occupational exposure limits (OELs), the risk index (R) of the exposure ratio method (1.694±0.433) was lower than those of the index method (2.344±0.317) and the composite index method (2.327±0.317) (P < 0.001). When 1/2 OELs ≤ EC < OELs, there was no significant difference in the R values of the exposure ratio method (2.966±0.138), the index method (2.916±0.206), and the composite index method (2.924±0.195) (P>0.05). When EC ≥ OELs, the R of the exposure ratio method (3.398±0.289) was higher than those of the index method (2.802±0.283) and the composite index method (2.887±0.279) (P < 0.001). The consistency of the assessment results between the exposure ratio method and the index method was poor (weighted Kappa=0.118, P < 0.001), that between the exposure ratio method and the composite index method was also poor (weighted Kappa=0.136, P < 0.001), and that between the index method and the composite index method was excellent (weighted Kappa=0.977, P < 0.001). For positions with EC exceeding OELs, the three assessment results were all above medium risk, consistent with the determination results of OELs. The manual spraying positions were evaluated as negligible-risk positions and low-risk positions by the three assessment methods, inconsistent with the results of occupational health examination.

Conclusion

The three semi-quantitative risk assessment methods can identify key positions with occupational health hazards, but the results for the manual spraying positions are conservative. Because the results of the three methods are related to EC, it is suggested to choose appropriate assessment methods according to the EC of target occupational hazardous factors.

HTML全文

图 1 不同浓度等级下三种半定量职业健康风险评估方法的风险等级比较

[注(Note)] *:P < 0.001。

Figure 1. Risk levels for different concentration levels of target hazards by three semi-quantitative occupational health risk assessment methods

表 1 武汉市4家汽车整车制造企业职业卫生基本情况

Table 1 General occupational health information in four automobile manufacturers in Wuhan

企业Enterpris 年生产规模/万辆Annual production

capacity/104

vehicles 工人数

Workers 岗位

Position 原辅料

Materials 日接触

时问/h

Daily

exposure

hours 日使

用量

Daily

usage 周工作

天数/d

Weekly

work

days 作业方式

Operation 防护措施

Protective measure A 25 4681 点焊

Spot welding - 9.5 - 5 手工/半自动

Manual/semi-automatic 全面通风,个人防护

General ventilation,personal protection MIG焊

MIG welding 焊丝

Welding wire 9.5 20 kg 5 手工

Manual 局部通风,个人防护

Local ventilation, personal protection 打磨

Polishing - 9.5 - 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection 手工喷漆

Manual spraying 油漆

Paint 9.5 24 L 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection B 15 1641 点焊

Spot welding - 7.5 - 5 半自动

Semi-automatic 全面通风,个人防护

General ventilation, personal protection MIG焊

MIG welding 焊丝

Welding wire 0.5 1 kg 5 手工

Manual 局部通风,个人防护

Local ventilation, personal protection 打磨

Polishing - 7.5 - 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection 手工喷漆

Manual spraying 油漆

Paint 1.0 18 L 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection C 8 1 412 点焊

Spot welding - 8.0 - 5 手工/半自动

Manual/semi-automatic 全面通风,个人防护

General ventilation,personal protection MIG焊

MIG welding 焊丝

Welding wire 8.0 18 kg 5 手工

Manual 局部通风,个人防护

Local ventilation, personal protection 打磨

Polishing - 8.0 - 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection 手工喷漆

Manual spraying 油漆

Paint 8.0 36 L 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection D 15 1815 手工点焊

Manual spot welding - 10.0 - 5 手工/半自动

Manual/semi-automatic 全面通风,个人防护

General ventilation,personal protection MIG焊

MIG welding 焊丝

Welding wire 10.0 20 kg 5 手工

Manual 局部通风,个人防护

Local ventilation, personal protection 手工喷漆

Manual spraying 油漆

Paint 10.0 28 L 5 手工

Manual 全面通风,个人防护

General ventilation, personal protection

表 2 三种半定量职业健康风险评估方法对武汉市4家汽车整车制造企业主要职业病危害因素的评估结果比较

Table 2 Comparison of grading occupational health hazardous factors by three semi-quantitative occupational health risk assessment methods in four automobile manufacturers in Wuhan

企业Enterprise 岗位

Position 危舍因素

Hazardous factor 检测点数

Detected

sites OELs/

mg.m-3 Ctwa/

mg.m-3 HR 接触比值法

Exposure ratio method 指数法

Index method 综合指数法

Composite index method ER R ER R ERR A 点焊

Spot welding 电焊烟尘

Welding fume 21 4 1.305±0.982 3 2.238±0.62 2.572±0.320 2.340 2.650 2.309±0.107 2.631±0.059 二氧化氮

Nitrogen dioxide 21 5 0.084±0.017 2 1.000 1.414 2.340 2.163 1.974 1.414 MIG焊

MIG welding 电焊烟尘

Welding fume 9 4 0.811±0.542 3 1.778±0.44 2.290±0.316 2.343 2.720 2.343±0.100 2.651±0.057 锰及其无机化合物

Manganese and its

inorganic compounds 9 0.15 0.046±0.068 2 1.778±1.09 1.817±0.536 2.466 2.233 2.312±0.186 2.149±0.085 二氧化氮

Nitrogen dioxide 9 5 0.093±0.043 2 1.000 1.414 2.466 2.233 2.168 2.082 打磨

Polishing 砂轮磨尘

Grinding wheel dust 6 8 1.300±1.620 3 1.500±0.83 2.063±0.541 3.129 3.064 2.727±0.225 2.858±0.116 手工喷漆

Manual

spraying 甲苯

Toluene 9 50 < 0.03 2 1.000 1.414 2.280 2.135 2.057 2.028 二甲苯

Xylene 9 50 0.992±2.010 2 1.111±0.33 1.479±0.195 2.188 2.092 2.004±0.060 2.002±0.029 乙酸丁酯

Butyl acetate 9 200 0.328±0.418 2 1.000 1.414 2.188 2.092 1.984 1.922 丁酮

Methyl ethyl ketone 9 300 0.127±0.212 2 1.000 1.414 2.280 2.135 2.057 2.135 丁醇

Butanol 9 100 5.333±11.30 2 1.111±0.33 1.479±0.195 2.188 2.092 2.004±0.060 2.002±0.029 B 点焊

Spot welding 电焊烟尘

Welding fume 12 4 0.531±0.290 3 1.750±0.45 2.270±0.324 2.512 2.745 2.352±0.119 2.656±0.068 二氧化氮

Nitrogen dioxide 12 5 0.043±0.017 2 1.000 1.414 2.512 2.241 2.154 2.076 MIG焊

MIG welding 电焊烟尘

Welding fume 3 4 0.767±0.158 3 2.000 2.449 1.648 2.223 1.694 2.449 锰及其无机化合物

Manganese and its

inorganic compounds 3 0.15 0.016±0.008 2 1.667±0.57 1.805±0.338 1.648 1.815 1.641±0.092 1.810±0.051 二氧化氮

Nitrogen dioxide 3 5 0.021±0.007 2 1.000 1.414 1.648 1.815 1.534 1.752 打磨

Polishing 砂轮磨尘

Grinding wheel dust 6 8 2.832±2.660 3 1.833±0.75 2.302±0.490 2.724 2.859 2.523±0.183 2.302±0.490 手工喷漆

Manual spraying 甲苯

Toluene 3 50 < 0.03 2 1.000 1.414 1.919 1.959 1.769 1.414 二甲苯

Xylene 3 50 < 0.05 2 1.000 1.414 1.842 1.919 1.707 1.848 乙酸丁酯

Butyl acetate 3 200 0.205±0.174 2 1.000 1.414 1.842 1.919 1.707 1.848 丁醇

Butanol 3 100 < 0.3 2 1.000 1.414 1.842 1.919 1.707 1.848 C 点焊

Spot welding 电焊烟尘

Welding fume 8 4 1.025±1.316 3 2.000±0.92 2.397±0.539 2.727 2.859 2.556±0.190 2.397±0.539 二氧化氮

Nitrogen dioxide 8 5 0.046±0.329 2 1.000 1.414 2.724 2.334 2.305 2.147MIG焊

MIG welding 电焊烟尘

Welding fume 4 4 5.975±4.055 3 1.494±1.01 3.197±0.613 2.904 2.952 2.962±0.166 2.980±0.084 锰及其无机化合物

Manganese and its

inorganic compounds 4 0.15 0.455±0.601 2 3.500±1.73 2.581±0.671 2.904 2.410 2.946±0.222 2.426±0.092 二氧化氮

Nitrogen dioxide 4 5 0.082±0.043 2 1.000 1.414 2.904 2.410 2.494 2.233 打磨

Polishing 砂轮磨尘

Grinding wheel dust 3 8 1.433±0.777 3 2.000 2.449 3.129 3.064 2.904 2.952 手工喷漆

Manual

spraying 甲苯

Toluene 3 50 0.092±0.775 2 1.000 1.414 2.280 2.135 2.057 2.028 二甲苯

Xylene 3 50 1.420±0.956 2 1.000 1.414 2.188 2.092 1.984 1.992 乙酸丁酯

Butyl acetate 3 200 42.767±14.7 2 2.000 2.00 2.188 2.092 2.163 2.080 丁酮

Methyl ethyl ketone 3 300 1.770±0.461 2 1.000 1.414 2.280 2.135 2.057 2.028 丁醇

Butanol 3 100 2.527±0.523 2 1.000 1.414 2.188 2.092 1.984 1.992 D 手工点焊

Manual spot spraying 电焊烟尘

Welding fume 18 4 2.661±1.330 3 2.722±0.66 2.837±0.350 2.954 2.977 2.903±0.119 2.950±0.061 二氧化氮

Nitrogen dioxide 18 5 0.122±0.014 2 1.000 1.414 2.954 2.431 2.466 2.221 MIG焊

MIG welding 电焊烟尘

Welding fume 6 4 4.950±2.487 3 3.833±0.75 3.378±0.333 3.107 3.053 3.196±0.090 3.096±0.044 锰及其无机化合物

Manganese and its

inorganic compounds 6 0.15 0.118±0.119 2 2.667±1.15 2.276±0.478 3.107 2.493 3.019±0.175 2.457±0.071 二氧化氮

Nitrogen dioxide 6 5 0.123±0.015 2 1.000 1.414 3.107 2.493 2.643 2.299 打磨

Polishing 砂轮磨尘

Grinding wheel dust 3 8 4.733±3.523 3 2.667±1.15 2.788±0.586 3.129 3.064 3.023±0.205 3.010±0.101 手工喷漆

Manual

spraying 甲苯

Toluene 6 50 < 0.03 2 1.000 1.414 2.280 2.135 2.057 2.028 二甲苯

Xylene 6 50 < 0.05 2 1.000 1.732 2.188 2.562 1.984 2.440 乙酸丁酯

Butyl acetate 6 200 1.547±1.548 2 1.000 1.414 2.188 2.092 1.984 1.992 异丙醇

Isopropyl alcohol 6 350 < 0.47 2 1.000 1.414 2.280 2.135 2.057 2.028 合计

Total 292 1.857±0.628 2.401±0.349a 2.302±0.375a[注] HR:危害分级;ER:接触等级;R:风险指数:1=可忽略风险,2=点风险,3=中等风险,4=高风险,5=极高风险;a:与接触比值法比较,P < 0.001。

[Note] HR: Hazard rating; ER: Exposure rating; R: Risk; 1=Negligible risk; 2=Spot risk; 3=Medium risk; 4=High risk; 5=Very high risk; a: Compared with exposure ratio method, P < 0.001.

参考文献(16)

[1] 曹素红.两种职业健康风险评估模型在上海市奉贤区某汽车零部件制造企业中的运用[J].职业与健康, 2018, 34(20):2740-2744. http://d.old.wanfangdata.com.cn/Periodical/zyyjk201820002 [2] 刘文慧, 苏世标, 徐海娟, 等.职业健康风险评估方法应用研究进展[J].中国职业医学, 2016, 43(4):487-490. http://d.old.wanfangdata.com.cn/Periodical/zgzyyx201604025 [3]United States Environmental Protection Agency. Risk assessment guidance for superfund volume Ⅰ: human health evaluation manual (Part F, supplemental guidance for inhalation risk assessment, EPA-540-R-070-002OSWER 9285.7-82 January 2009)[R]. Washington. DC: Office of Superfund Remediation and Technology Innovation Environmental Protection Agency, 2009.

[4]The University of Queensland. Occupational health and safety risk assessment and management guideline[R]. Australia: Occupational Health and Safety Unit, 2004.

[5]Ministry of Manpower Occupational Safety and Health Division. A semi-quantitative method to assess occupational exposure to harmful chemicals[R]. Singapore: Ministry of Manpower Occupational Safety and Health Division, 2005.

[6] 工作场所化学有害因素职业健康风险评估技术导则: GBZ/T 298-2017[S].北京: 中国标准出版社, 2018. [7] 工作场所空气中有害物质监测的采样规范: GBZ 159-2004[S].北京: 人民卫生出版社, 2006. [8] 郭轶斌, 郭威, 秦宇辰, 等.基于Kappa系数的一致性检验及其软件实现[J].中国卫生统计, 2016, 33(1):169-170, 174. http://d.old.wanfangdata.com.cn/Periodical/zgwstj201601058 [9] 苏艺伟, 李艳华, 郭尧平, 等. 2017年广州市某汽车厂职业病危害因素及职工健康状况[J].职业与健康, 2018, 34(17):2310-2313, 2317. http://d.old.wanfangdata.com.cn/Periodical/zyyjk201817002 [10] 路艳艳, 柴剑荣, 徐承敏, 等.杭州市新建汽车整车制造项目职业病危害控制效果[J].职业与健康, 2017, 33(15):2029-2033. http://d.old.wanfangdata.com.cn/Periodical/zyyjk201715004 [11] 张守刚, 张荣, 宋伟, 等.某新建汽车生产线建设项目职业病危害控制效果评价[J].职业与健康, 2009, 25(15):1653-1655. http://d.old.wanfangdata.com.cn/Periodical/zyyjk200915042 [12] 李旭东, 丁俊, 刘明, 等.三种职业健康风险评估方法评估涂料生产企业有机溶剂风险的应用比较[J].预防医学, 2018, 30(8):794-798. http://d.old.wanfangdata.com.cn/Periodical/zjyfyx201808009 [13] 许振国, 张敏红, 刘莉莉, 等.加油站苯接触岗位职业健康风险评估[J].中国职业医学, 2018, 45(6):762-765. http://d.old.wanfangdata.com.cn/Periodical/zgzyyx201806021 [14] 丁俊, 苏世标, 靳雅丽, 等.家具生产企业有机溶剂的三种健康风险评估方法比较[J].预防医学, 2019, 31(4):400-404. doi: 10.3969/j.issn.1006-3110.2019.04.005 [15] 田亚锋, 刘开钳, 吴礼康, 等.比较三种职业健康风险评估模型在蓄电池生产企业的应用[J].预防医学, 2018, 30(12):1248-1251. doi: 10.3760/cma.j.issn.0253-9624.2018.12.011 [16] 陈琳, 马炜钰, 靳雅丽, 等.广州汽车4S店化学有害因素职业健康风险评估[J].中国职业医学, 2018, 45(6):789-792. http://d.old.wanfangdata.com.cn/Periodical/zgzyyx201806028施引文献

补充资料

审稿意见

勘误/撤稿

图(1) / 表(2)

计量 文章访问数: HTML全文浏览量: 0 PDF下载量: 出版历程 收稿日期: 2019-08-29 录用日期: 2019-12-29 网络出版日期: 2022-11-20 刊出日期: 2020-02-24目录

相关知识

煤焦油沥青职业健康风险评估分析

常用汽车内饰材料的健康效应及控制策略

关注车内健康,倡导健康出行 中国汽车健康指数引领汽车行业加速发展

中国汽车健康指数

电动汽车电磁辐射并不高 中国汽车健康指数测评

高标准把控车内环境健康 全国首个《新能源汽车车内空气质量健康评价指南》在深实施

健康汽车怎么看?汽车健康指数:数据告诉你全文

健康风险评估的种类包括

安全健康风险评估.doc

出行健康不容忽视,做“最健康的汽车”,极狐汽车是认真的!

网址: 三种半定量职业健康风险评估方法在汽车整车制造业中的应用 https://m.trfsz.com/newsview701261.html